刘长宜,教授,博士生导师,1989年10月出生,目前就职于吉林大学工程仿生教育部重点。于2019年在吉林大学机械学院获工学博士学位(导师 赵宏伟教授),2020年1月进入吉林大学工程仿生教育部重点实验室开展研究工作(合作导师 任露泉院士),主要从事材料力学性能测试技术(固体火箭发动机推进剂测试、仿生材料与生物力学测试),仿生六足机器人等研究工作。近年来以第一/通讯作者在《Small》,《IJMS》,《Energy》,《IEEE TIM》等期刊发表论文30余篇,授权国家发明专利7件、欧洲专利1件,参与编制行业标准2项。主持国家自然科学基金、国家部委重点项目、吉林省重大专项等科研项目10余项,累计可支配科研经费逾800万元,自主研制的系列化材料力学性能原位测试仪器在深圳粒子院、航天四院等单位得到应用。获2023“中国机械工业技术发明一等奖”、“第六届全国高等学校教师自制实验教学仪器大赛一等奖”、“庆祝中华人民共和国成立70周年吉林彩车工作先进个人”等奖励。

研究领域:材料力学性能测试技术,航天材料测试技术、特种车辆

联系方式:liuchangyi@jlu.edu.cn

办公地址:吉林大学南岭校区第三教学楼C154;仿生楼410;

招生情况:每年招收硕士研究生1-2名,博士研究生1名,科研方向覆盖仪器研发、新材料研究等方向;承担包括基础研究、工程技术、国防领域科研项目,能够满足不同学生的兴趣和未来发展规划。

招收专业:仿生科学与工程(学硕、学博)、机械(专硕、专博)

欢迎机械工程、材料、汽车等专业对机械仿生学研究感兴趣的优秀学生报考。

主持科研项目

[1]国家自然科学基金项目,接近服役环境的固体推进剂力学性能原位测试新技术研究(52205565),2023.01-2025.01,30万元,项目负责人.

[2]“慧眼行动”创新成果转化应用项目,固体推进剂力学性能原位测试新技术研究(F88E5A31),2024.01-2025.12,134.6万元,项目负责人.

[3]国家部委预先研究项目,2022G014J00047, 2021.8-2023.8,200万元,项目负责人.

[4]国家部委重大项目, 2023X024J00160,2023.12-2026.11,90万元,课题负责人.

[5]吉林省科技厅国家重点实验室重大专项,滑板式电动车底盘测试关键技术研发(SKL202302016),2023.1-2025.1,100万元,课题负责人.

[6]吉林省科技厅重大科技专项,基于智能设备的焊接质量原位检测技术研发(20210301037GX),2021.10-2023.10,90万元,课题负责人.

[7]吉林省自然科学基金项目,火箭发动机衬层界面力学性能原位测试分析技术与表征研究(20240101134JC),2024.01-2026.12,12万元,项目负责人.

[8]中国博士后科学基金,面向生物体植入器件无线供电的磁电复合俘能技术研究(2020M681038),2020.11-2022.07,8万元,项目负责人.

[9]广东富华机械集团有限公司(横向课题),轮式装载机单手柄集成转向系统开发,2020.03-2023.03,100万元,项目负责人.

[10]内蒙古第一机械集团有限公司(横向课题),腿足系统性能研究,2024.06-2025.12,40万元,项目负责人.

[11]太原理工大学(横向课题,依托威海仿生研究院),兼容扫描电镜原位高温拉伸仪研制,2022.1-2023.1,38.5万元,项目负责人.

[12]国家重大科学仪器设备开发专项,材料微观力学性能原位测试仪器研制与应用(2012YQ030075),2012.10-2016.10,6527万元,主要完成人.

[13]国家重点研发计划(大科学装置前沿研究),中子与x射线融合成像下固体推进剂力学行为原位表征新技术(2022YFA1600053),2022.12-2027.11,1850万元,主要参加人.

发表学术论文

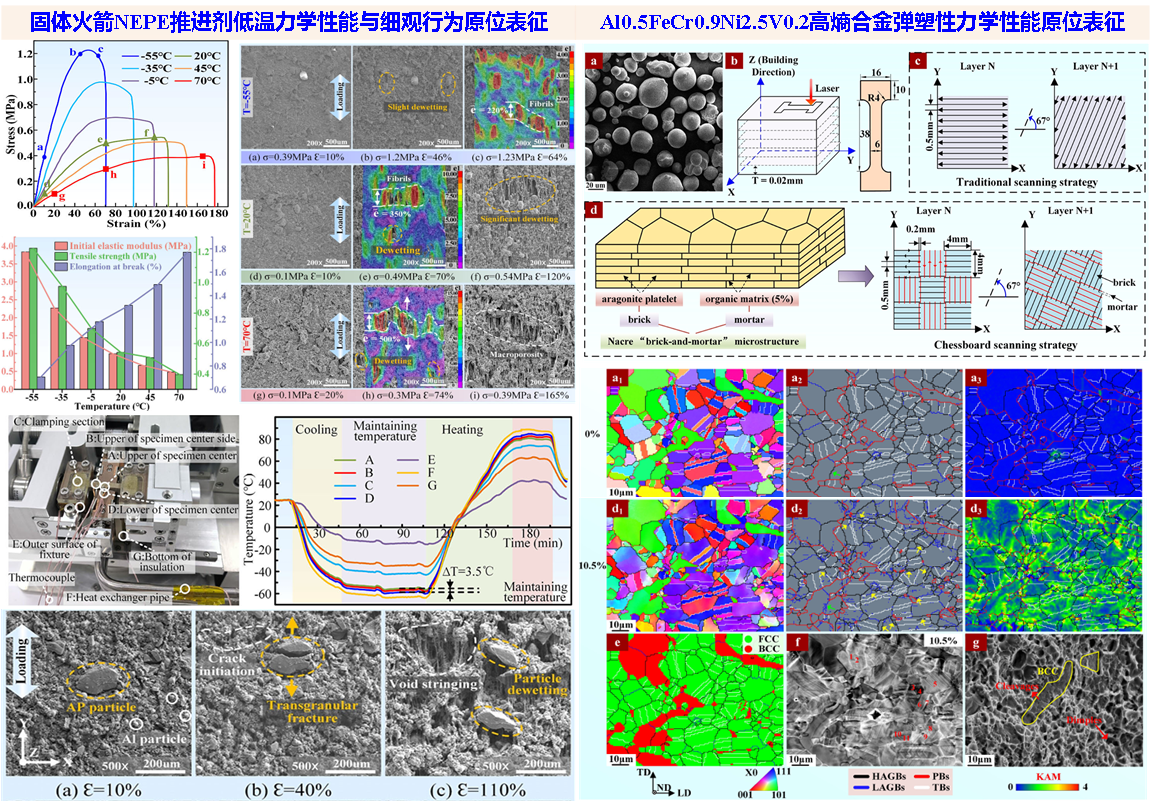

航空航天关键材料力学性能测试方向

[1]Kaisheng Yang , Lipeng Sang, Changyi Liu*, Chuntao Li, Xingyu Liu , Wenjuan Xing, Hu Huang, Hongwei Zhao*. Development of In Situ SEM Mechanical Testing Instrument for Solid Propellants Under Near-Service Conditions [J]. IEEE Transactions on Instrumentation and Measurement, 2025, 74: 6002214.

[2]Zhonghan Yu, Wenjuan Xing, Xianke Li, Jinzhe Wang, Changyi Liu*, Hongwei Zhao*. In-situ EBSD unveils intrinsic mechanisms by which hierarchical microstructure enhances ductility in laser powder bed fusion Al0.5FeCr0.9Ni2.5V0.2 high-entropy alloy[J]. Materials Science & Engineering A,2025, 948:149342.

[3]Wenjuan Xing, Zhonghan Yu, Changyi Liu*, Hongwei Zhao*. In-situ EBSD investigation of superior strength-ductility synergy achieved through multiscale heterogeneous structure design in Al0.25FeCoNiVTi0.1 high-entropy alloy[J]. Materials Science & Engineering A,2025, 923:147721.

[4]Wenjuan Xing, Zhonghan Yu, He Shao, Changyi Liu* and Hongwei Zhao*. In-Situ EBSD investigation of how annealed twins produce excellent strength-ductility synergy in Al0.25FeCoNiV duplex high-entropy alloy [J]. Materials Science & Engineering A, 2024, 30: 7607~7620.

[5]Zhonghan Yu, Wenjuan Xing, Changyi Liu*, Kaisheng Yang, He Shao, Hongwei Zhao*.Construction of multiscale secondary phase in Al0.25FeCoNiV high-entropy alloy and in-situ EBSD investigation [J]. Journal of Materials Research and Technology, 2024, 30: 7607~7620.

[6]Wenjuan Xing, Zhonghan Yu, Changyi Liu**, Yunlai Zhao, Yunlong Zhu, Jiayin Zhou, Kaisheng Yang, Hongwei Zhao*. In-situ EBSD investigation of excellent strength-ductility synergy mechanism achieved by thermal-mechanical processing of Al0⋅25FeCoNiV high-entropy alloy [J]. Materials Science & Engineering A, 2024, 902: 146581.

[7]Wenjuan Xing, Zhonghan Yu, Xianke Li, Hongyang Zhang, Hao Wu, Zhenqiao Zhang, Zhijie Zhang, Changyi Liu*, Hongwei Zhao. Multiscale heterostructure construction and dislocation density modulation for enhanced wear resistance in novel Al0.25FeCoNiVTi0.1 high-entropy alloy [J]. Wear, 576-577(2025) 206120.

[8]Wenjuan Xing, Zhijie Zhang, Jiayin Zhou, Zhijie Zhang, Changyi Liu*, Hongwei Zhao*. Study of the friction stir welding process and mechanical behavior of 7075/ 6061 heterogeneous aluminum alloys based on in-situ EBSD/DIC testing [J]. Materials Today Communications, 2025, 44:112000.

[9]Zhonghan Yu, Zhijie Zhang, Wenjuan Xing, Jinzhe Wang, Xianke Li, Zhenqiao Zhang, Changyi Liu*, Hongwei Zhao*. Nacre-inspired chessboard scanning strategy enables a broad process window and enhanced mechanical properties in LPBF-processed AlFeCrNiV high-entropy alloy[J]. Materials Today Communications, 2025, 49:114124. Journal of Materials Science,

[10]Zhonghan Yu, Wenjuan Xing, Changyi Liu*, Hongwei Zhao*. Modulation of thermal cycles and annealing parameters to enhance wear and corrosion resistance of plasma�cladded Fe�based coatings[J]. Journal of Materials Science, 60, 24701–24731 (2025)

[11]Changyi Liu,Hongwei Zhao*, Zhichao Ma, Yuansen Qiao, Kun Hong, Zhuang Ren, Jianhai Zhang, Yongmao Pei*. Novel instrument for characterizing comprehensive physical properties under multi-mechanical loads and multi-physical field coupling conditions [J]. Review of Scientific Instruments, 2018, 89: 25112.

[12]Changyi Liu, Zhichao Ma, Liming Zhou, Yuansen Qiao, Zeyang Liu, Xianhua Liu, Shizhong Zhang, Hongwei Zhao*. Correction method for mechanical performance testing instrument with tension- torsion coupling loading [J]. Measurement Science and Technology, 2018, 29: 105901.

[13]邢文娟,于忠瀚,刘长宜*,赵宏伟**. 材料力学性能原位测试技术:发展与应用 [J]. 激光与光电子学进展,2023,第60卷 第3期.

仿生材料与生物力学方向

[1]Zhuang Ren, Changyi Liu*, Minghe Li, Wenwei Ge, Liming Zhou, Hongwei Zhao*, Lihua Tang, Luquan Ren. Comparative analysis of energy harvesting by magnetoelectric components in a simulated biological environment [J]. International Journal of Mechanical Sciences, 2025, 288:110042.

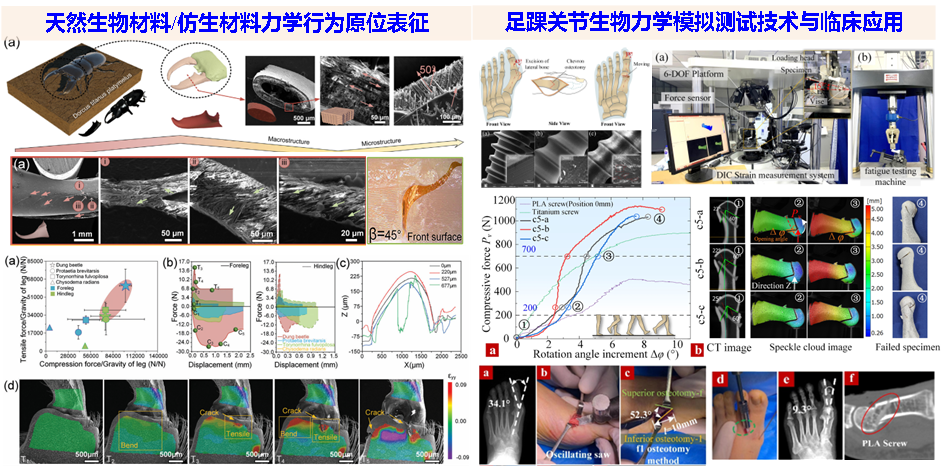

[2]Zhiwei Tuo, Zhaohua Lin, Yan Xia, Hong Xu, Yunhong Liang* , Nan Zhang, Jiandong Cui, Sen Lin, Changyi Liu* . Biomimetic 3D printing of hierarchical structures: Decoding the multi-scale mechanical design principles in Xylotrupes gideon linneaus horns[J]. Construction and Building Materials, 499 (2025) 144103.

[3]Zhiwei Tuo, Yu Shi, Xianyan Sun, Jiandong Cui, Kaisheng Yang, Yunhong Liang∗, Changyi Liu∗, Zhaohua Lin, Zhiwu Han, Luquan Ren. Study of the influence of macro-structure and micro-structure on the mechanical properties of stag beetle upper jaw [J]. Acta Biomaterialia, 2024, 186: 342-353. (一区top,影响因子9.4)

[4]Zhiwei Tuo, Kaisheng Yang, Suqian Ma, Jiandong Cui, Yu Shi, Hongwei Zhao, Yunhong Liang,* Changyi Liu*, Zhaohua Lin, Zhiwu Han,* and Luquan Ren. Multi-Level Structural Enhancement Mechanism of the Excellent Mechanical Properties of Dung Beetle Leg Joint [J]. SMALL, 2024: 2311588. (一区top,影响因子13)

[5]Changyi Liu, Dongqi Li, Songning Ma, Hanyang Zhang*, Shizhong Zhang, Fei Chang, Peng Liu, Hongwei Zhao, Shuo Jin. Modified chevron osteotomy for the treatment of hallux valgus with unison bioabsorbable screws: Biomechanical research and clinical applications [J]. Journal of Biomechanics, 2025,180:112527.

[6]Changyi Liu, Lingshuai Huang, Hanyang Zhang*, Fei Chang *, Shichao Li , Songning Ma, Yu Zhang, Luquan Ren. Biomechanical comparison between bioabsorbable and medical titanium screws in distal chevron osteotomy of first metatarsal in hallux valgus treatment [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2022, 131: 105260.

[7]Chi Zhang, Changyi Liu*, Hongwei Zhao*. Mechanical properties of brain tissue based on microstructure [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2022, 126: 104924.

[8]Bin Nie, Shuihui Ren, Wanqing Li, Liming Zhou∗, Changyi Liu∗. The hygro-thermo-electro-mechanical coupling edge-based smoothed point interpolation method for the response of functionally graded piezoelectric structure under hygrothermal environment [J]. Engineering Analysis with Boundary Elements, 2021,130: 29-39.

[9]Liming Zhou, Jiye Wang, Xiaolin Li, Changyi Liu∗, Peng Liu∗, Shuhui Ren, Ming Li. The magneto-electro-elastic multi-physics coupling element free Galerkin method for smart structures in statics and dynamics problems [J]. Thin-Walled Structures, 2021, 1169: 108431.

[10]Ming Li, Liming Zhou*, Changyi Liu*. The multi-physical cell-based smoothed finite element method for analyzing transient behavior of functionally grade magneto-electro-elastic [J]. Thin-Walled Structures, 2020,155: 106876.

[11]Ren Zhuang, Lihua Tang, Jiucheng Zhao, Shizhong Zhang, Changyi Liu* and Hongwei Zhao*. Comparative study of energy harvesting performance of magnetoelectric composite based piezoelectric beams subject to varying magnetic field [J]. Smart Materials and Structures, 2022, 31: 105001.

腿足式运动平台与特种车辆方向

[1]Jiyu Feng, Wei Chen, Changyi Liu, et al. Work-Phase Recognition in Construction Machinery Using Gated Recurrent Unit with Attention and Fractional Calculus Features [J]. Computer-Aided Civil and Infrastructure Engineering,2025;1–25(一区top,C刊)

[2]Jiyu Feng, Wei Chen, Changyi Liu, Xinhui Liu, Bingwei Cao*, Feixiang Xu. Advancements and challenges in earthmoving equipment automation using core technologies [J]. Automation in Construction, 179 (2025) 106472. (一区top,影响因子10.6)

[3]Hang Li , Xinhui Liu, Bingwei Cao, Changyi Liu*, Jianwen Yang** and Wei Chen. Optimisation of downdraft gasifier in biomass-fuelled power generation system: Experimental analysis and chemical kinetics modelling with tar cracking [J]. Energy, 2024, 313: 133924.(一区top,影响因子9)

[4]Jinshi Chen, Dongyang Huo, Changyi Liu *, Han Zhang, Yuqi Wang. Design and modeling of hardware-in-loop test bench for hydraulic excavator based on dynamic load emulation [J]. Automation in Construction, 2022, 137: 104196. (一区top,影响因子10.6)

[5]Jiyu Feng, Wei Chen, Changyi Liu*, Peng Tan*, Fuxiang Du, Wenjie Yang, Yichuan Wang. Experimental investigation of the intermittent spray heat transfer characteristics of nanofluids in single- and two-phase states [J]. Applied Thermal Engineering, 2024, 248: 123222. (一区top,影响因子5.8)

[6]Peng Tan, Xinhui Liu, Changyi Liu*, Jiyu Feng, Kuo Yang. Experimental study on heat transfer performance of a series combined microchannel heat dissipation system based on Al2O3 nanofluid [J]. Applied Thermal Engineering, 2024, 240: 122237. (一区top,影响因子5.8)

[7]Jiyu Feng, Wei Chen, Peng Tan*, Changyi Liu*, Hao Wang, Fuxiang Du. Experimental study on heat-transfer characteristics of spray cooling for microchannel radiators [J]. Applied Thermal Engineering, 2024, 245: 122913. (一区top,影响因子5.8)

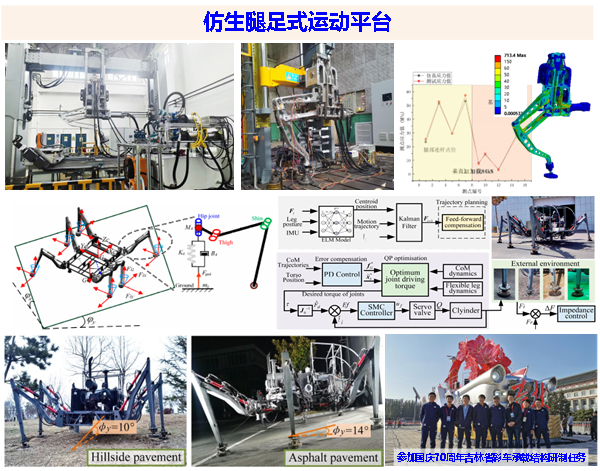

[8]Kuo Yang, Xinhui Liu, Changyi Liu,* and Xurui Tan. A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot [J]. Biomimetics, 2023, 8: 561.

[9]Kuo Yang, Xinhui Liu, Changyi Liu,* and Ziwei Wang. Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains [J]. Agriculture, 2023, 13: 2131.

授权发明专利

[1]刘长宜,雍健辉,赵宏伟等.一种扫描电镜内微型气体氛围控温装置:ZL 202410873542.3[P]. 2025.03.28(发明专利,已授权,第一发明人)

[2]刘长宜, 李鸣鹤, 马嵩宁等. 扫描电镜下的准静态原位双轴拉伸力学性能测试装置: ZL 202110479236.8[P]. 2022.06.07.(发明专利,已授权,第一发明人)

[3]刘长宜, 黄令帅, 李鸣鹤等. 扫描电子显微镜中原位静-动态疲劳力学性能测试仪器: ZL 202110502918.6[P]. 2022.06.14.(发明专利,已授权,第一发明人)

[4]Zhao H W;Liu C Y;Ma Z C;Ren L Q;Liu X H;Zhou Y C;Sun J W;Qiao Y S;Ren Z;Hong K;Zhang F;Fan Z Q;Zhang Z H;Hu Y;Dong J S,Combined load mode mechanical-electrical and thermal-magnetic coupling material performance in-situ test instrument and method, EP 3 396 353 B1. (欧洲发明专利)

[5]刘长宜,冯吉宁,杨子康等. 一种独立分区高效喷淋式液冷系统: ZL 20201 1382906.6[P]. 2021.12.17. (发明专利,已授权,第一发明人)

[6]刘长宜, 李鸣鹤, 黄令帅等. 用于生物植入设备的无线充电器件: ZL 20211 0370597.9[P]. 2022.02.25. (发明专利,已授权,第一发明人)

[7]赵宏伟,刘长宜,马志超;任露泉等.复合载荷模式力电热磁耦合材料性能原位测试仪器与方法, ZL 2015 1 0973083.7[P],授权公告日2018年 08月 10日.(发明专利,已授权)

[8]赵宏伟,刘长宜,马志超等.针对小型原位拉伸仪拉伸变形测量的分体式微型引伸计,ZL 2017 1 1390004.5[P],授权公告日2024年02月02日.(发明专利,已授权)

参与制定标准

[1] 徐利霞、王学智、赵宏伟、刘长宜、徐忠根、乔元森、任露泉,固体材料原位拉伸-压痕复合力学性能测试系统,中国机械行业标准,JB/T 13225-2017

[2] 马志超、张金伟、赵宏伟、刘泽善、刘长宜、任壮、任露泉,固体材料原位拉伸-弯曲复合力学性能测试系统,中国机械行业标准,JB/T 13223-2017

获得奖励

[1]复杂机械载荷与多场耦合材料力学性能测试技术及应用,中国机械工业技术发明一等奖,第3完成人,2023.

[2]复杂工况材料力学性能测试仪,全国高校教师教学创新大赛一等奖,第6完成人,2021.

[3]复杂工况材料力学性能测试仪,高等学校教师自制实验教学仪器设备创新大赛路演铜奖,第6完成人,2021.

[4]庆祝中华人民共和国成立70周年吉林彩车工作先进个人,2019.

研究方向介绍

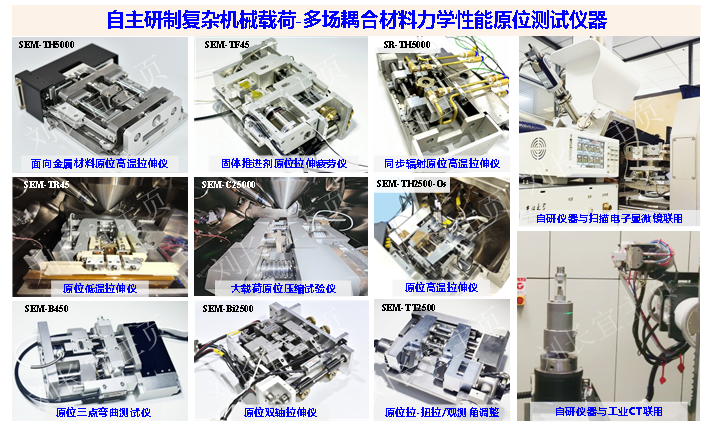

[1] 材料力学性能原位测试技术研究与应用

本方向聚焦材料力学性能的原位表征与测试技术,致力于突破传统测试方法在关联宏观力学性能与微细观损伤机理方面的局限。通过自主研制系列化专用仪器,实现在扫描电镜、工业CT等表征设备内部构建力�热耦合的复杂实验环境,同步完成力学加载与材料微观结构演化的动态观测。针对金属、高分子及纤维复合材料等不同体系的性能特点与服役工况,重点发展有限空间内复杂载荷加载技术、多物理场耦合环境构建等关键技术,开展专用测试仪器系统开发,为材料在多场耦合下的性能与失效行为分析提供方法支撑。

[2] 航空航天关键材料力学性能分析与表征

本方向致力于研究航空航天关键材料在高温、复杂氛围与多场耦合等极端环境下的力学性能演变与失效机理。这些极端工况对材料可靠性构成严峻挑战,因此,发展能够揭示其宏观性能与微观机制关联规律的研究方法至关重要。基于自主研制的原位测试技术,与航天科研院所合作,重点针对火箭固体推进剂等航天特种材料,系统开展能模拟实际服役环境的多尺度原位力学测试。通过与SEM、CT等先进表征平台实现技术联用,着力构建从“宏观力学性能—细观结构损伤”的全链条、跨尺度动态观测能力,进一步揭示固体推进剂在储运及服役条件下的性能演化规律与失效机制,为新一代高性能航天装备的设计与安全评价提供实验依据与方法支撑。

[3] 生物力学与医用材料力学性能测试

天然生物材料具有高度优化的多级结构与界面效应,其优异的力学性能源于精巧的微观构型与宏观表现的协同作用。利用原位测试技术对天然材料从宏观至微观尺度的力学行为与结构演化开展系统表征,旨在揭示其构效关系与变形机理,为仿生结构材料的设计提供理论依据,并进一步以天然材料多尺度结构为灵感,开展高性能仿生结构材料的设计与制备研究。在临床生物力学方面,与吉大二院合作面向骨科内固定与截骨手术中的关键力学问题,开展拇外翻矫正、跟骨骨折固定等术式的生物力学性能评估,为新型可降解内固定器械的优化设计与临床术式革新提供了关键基础数据,相关研究成果已直接服务于临床实践。

[4] 重载仿生足式运动平台与特种车辆

本方向面向高原山地复杂地形下的重载运输任务需求,致力于高承载、轻量化腿足机器人系统的设计与集成方法研究。重点突破电液伺服驱动、仿生结构设计与多关节协同控制等关键技术,研制具备高越障能力的轮腿复合式移动平台。参与研制国内规模最大的重载轮腿复合六足机器人平台。为验证系统在极端环境下的适应性,多次赴西藏、内蒙古等地区开展现场试验,系统评估其在低温及复杂地面条件下的运动性能与负载能力,为特殊环境下的无人化运输任务提供技术支撑。

科研条件

实验室具有完备的材料制备、材料测试表征、机械加工相关仪器设备(马弗炉、管式炉、扫描电镜、CT、金属3d打印等),包括20余台套自主研制的材料力学性能测试仪器,具备开展先进材料科学研究的条件,实验室环境及主要仪器设备如下: